|

|

#21

|

|||

|

|||

|

And the valve body is out!!!

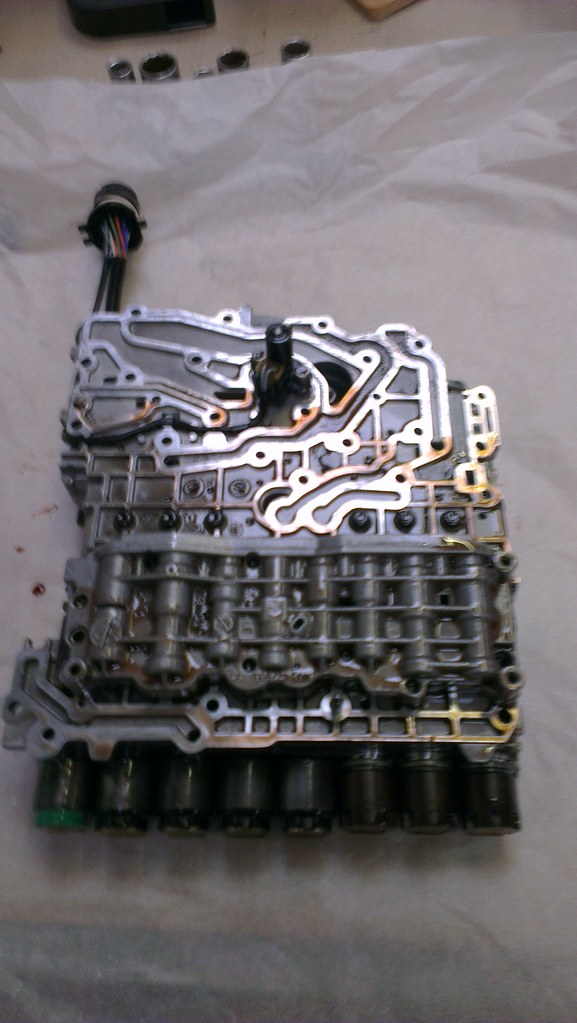

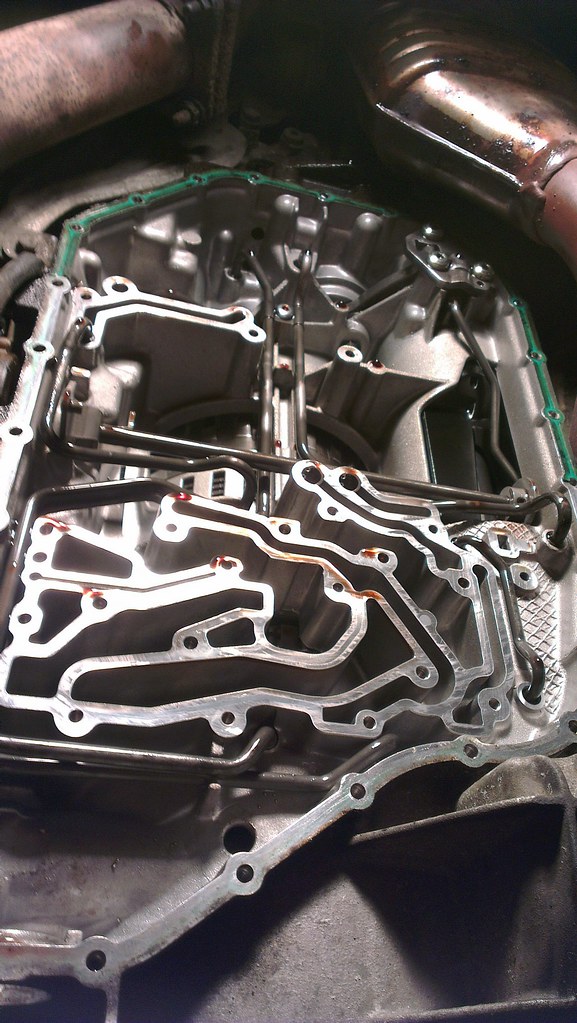

There is a big circlip on the electrical connection which meant i had to slightly modify my pliers to open wider, but success. The valve body from the top  Different angle  And the gearbox sans valve, just for interest  It's worth noting that there are differences between this box and the others i've seen online. Particularly that sensor and the wiring. You don't need to disconnect speed sensors as I guess it is all in the one that is sticking out the valve body! Lee |

|

#22

|

|||

|

|||

|

This brings back memories from when I was refitting my valve block over Christmas. How did you find the process ulfilias? Did you carry out the work at home or on a ramp?

__________________

Currently driving - '99 Silver A8 D2 FL 4.2 QS Currently for work - '08 Raven Blue T5 174 |

|

#23

|

|||

|

|||

|

Hi There,

I run a small manufacturing company and we are pretty quiet at the moment, so I have it at work. Bought a pair of decent axel stands, though I also have jacks under and a couple of other saftey precautions. Would kill for ramps at the moment.....I did almost contemplat fitting a two post one in our loading bay, but they tend to run to about a grand and they would possibly get in the way of the forklift and the like This morning I now have the PF car to the same point with the valve body out. This was easier to do as you don't have two bars crossing under the sump. The oil is pretty clean, though it has only done about a thousand miles since it got changed and all in 4th or reverse! The magnets have a bit of sludge, but no metal. However after removing the valve body, whatever that sensor is on the top jutting up (I'm guessing speed related) had 4-5 bits of 3-4mm metal stuck to it!!! While I know the error is with Solenoid 3. That can't be helping I will have a look better at what i can see inside the box after lunch! Lee |

|

#24

|

|||

|

|||

|

OK.....I want to cry!

Spent the past few days removing a valve body and then today the big day, removed "faulty one" and fitted the "working one" and i've just tested things and NO CHANGE!!! Still got Solenoid 3 Error  So all that work for nothing

|

|

#25

|

|||

|

|||

|

Well.. not for nothing.. have you checked the solenoid itself?

Could be that it's not the solenoid and there's something not happy further up the hydraulics (or a wiring problem)

__________________

2010 Jag XF 3.0D Portfolio S I know.. I know..

|

|

#26

|

|||

|

|||

|

Psyche - Changing the valve body, changed all the solenoids, and a lot of the pathways that could be blocked/problematic and a slug of the wiring loom (inside the gearbox)!

Basically from what I think I know about bits, it's not the gearbox at all. Could be TCU or wiring......Or there is something else causing the fault not registering or comming up as a symtom (though i'd expect more) Lee |

|

#27

|

|||

|

|||

|

Quote:

Are you saying you did all that work without checking solenoid resistance at the plug first?

__________________

Currently 8less 2011 Q7 S Line 3.0TDI, 2016 Tesla Model S 90D 8 history: 2006 A8 Sport 4.2TDI quattro SOLD, 1997 S8, reached end of life with gearbox failure |

|

#28

|

|||

|

|||

|

Hi ainarssems,

Alas not.....I guess that should have been done way back in the begining, before even the oil change. However I didn't know about it then! And due to circumstances - ie having the old car about and working on that first to see what was involved and speaking to gear box pro's saying it really needed a rebuild as they thought debris had fouled the sensor, it made sense to change the valve body, changing sensor, part of the wiring and any potential debris path! Since I have the old car albeit a newer model, I just tried changing the TCU (gearbox ecu). Alas it faults with a couple of software errors, so is incompatible. It doesn't throw the solenoid error, but it exhibits all the same symptoms, so i'm not sure! Interestingly while having a play (testing) I had my had on the gear selector and just turning the ignition from 0 to 1st position, before the car starts but electrics are on, there is a thump on the gear leaver and that's when the dashboard also errors, ie from clear, PRND432 to reded out, [PRND432]. This is before you go into reverse, neutral or anything! |

|

#29

|

|||

|

|||

|

Hi There

Well i used a long probe and a multimeter to trace out pin4 and pin16 on the TCM interface cable header  It looks like this and middle rown 4 sockets in from the left is pin4 and the 3rd from the right is pin16. Testing the two together and I get resistance of about 27! This means it must be the TCU then! Shame I get 18249 & 18263 on my new model one DG vs BL

|

|

#30

|

|||

|

|||

|

Quote:

__________________

Currently 8less 2011 Q7 S Line 3.0TDI, 2016 Tesla Model S 90D 8 history: 2006 A8 Sport 4.2TDI quattro SOLD, 1997 S8, reached end of life with gearbox failure |

|

|

|