Fixed it!

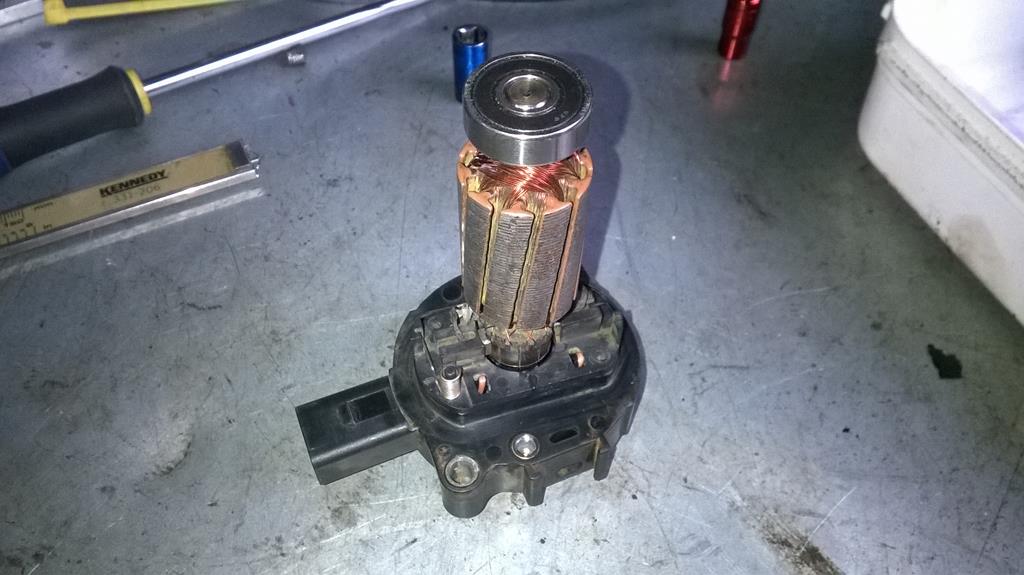

After cleaning it all up I discovered one of the windings on the armature had burned out, presumably from it being powered up while stalled:

So carefully soldered that back together

A continuity check across the commutator terminals showed the windings were all complete, so onward to the terminals in the end cap. These are brass, and had corroded away to blue powder. I ended up having to dig some plastic away with the dremel and cleaned up the tracks with a diamond burr so I could solder to them.

Not a lot to work with, but I got it done.

The brush plate broke in half when I dismantled the motor, but thats no biggie. I soldered wires to the two inductors and hot-glued everything in place.

Soldered the two wires to the terminals in the end cap, and then assembled it with the aid of some cyanoacrylate superglue.

You can see the bearing already in place here. Because of the way I've had to rebuild it with the wires I had to put the bearing in first and then press the motor shaft in to it in place. The factory would have assembled the brush plate and bearing first, then put the end cap on and soldered the terminals together.

I pressed the end bearing on first

Then pressed the armature in to the bearing in the end cap and we have this:

Cleaned up the housing:

The completed assembly just pushes in to the housing by hand and screws in place.

The motor drives the pump via magnetic coupling to save on having to seal the motor shaft against pressurised coolant. The magnet is attached to this steel flange then bolted to the motor shaft:

This had obviously been underwater too so cleaned it up with a bit of sandpaper then bolted it to the shaft. The magnetic ring is glued to the flange using the same structural acrylic that I used on the body studs, and the motor is complete:

Hooked up power to it and it works again